We use cookies for analytics. Read the privacy policy for more information.

ADS stories

In a world where precision and individuality are key factors for success, our team works hand in hand with customers and partners to deliver developments that are tailored to their objectives. From production processes and smart dosing systems to state-of-the-art, tailor-made measurement technology and optics, we design suitable solutions across multiple industries. On this page, you will learn about our projects and gain an impression of our skills and experience.

Vet-tech engineering | Start-up

Medtech engineering for dental treatment in horses.

Task

In collaboration with the start-up Swissvet USA, we have revolutionised veterinary dental treatment in horses. To keep horses in good health, it is necessary to grind their powerful teeth down manually from time to time. In the past, however, the tools available for this task were insufficient.

Dr Steiger, founder of the companies Swissvet USA and TERAFLOAT Switzerland and a practising vet, commissioned the team from ADS Engineering to develop a mobile device that allowed defined grinding of horses’ teeth while also making the grinding process much easier.

Implementation

The team worked with the customer to jointly establish and define the requirements for the device. For practical applications in stables and paddocks, it was vital for the device to be not only robust but also low-weight and battery-operated. Another essential feature was flexible adjustment of the drive shaft and therefore the grinding head in order to reach every position within the oral cavity. The device’s features are rounded off by rapid tool changing and the possibility of powerful illumination directly at the grinding head.

Customer benefits

- Practical everyday solution that saves time

- Defined grinding results

- Greater precision and independence

- Good handling thanks to high flexibility and low weight

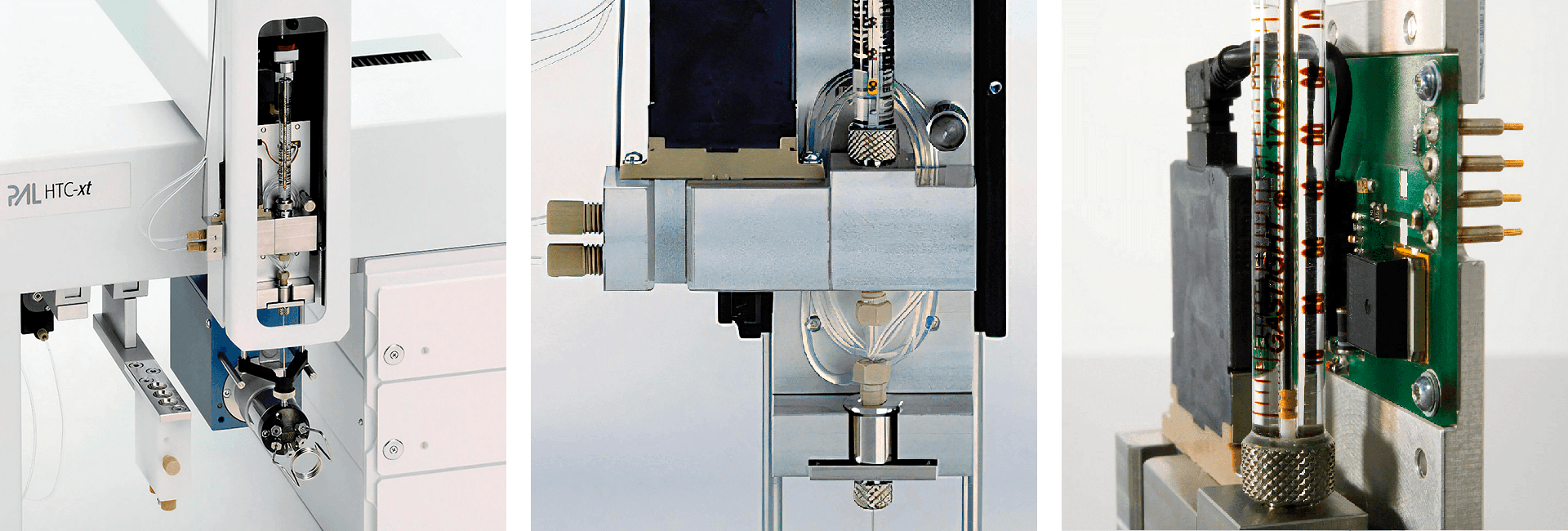

Product development | Industry

Realisation of a product family

Task

DECTRIS is now a leading high-tech company in the area of X-ray detectors for particle accelerators. As the largest spinoff from the Paul Scherrer Institute so far, the company has specialised in the development of “X-ray electronics” in particular. At ADS Engineering, we were tasked with developing a design concept for a product family and its mechanical implementation for the high-precision X-ray detectors, as well as with their prefabrication.

Implementation

We developed and optimised the DECTRIS product family as part of a creative development process. Design proposals were submitted using digital 3D models and physical rapid prototyping models. A potential new customer, the Japanese company Rigaku Corp., was so impressed with the new detector generation that it adopted it immediately.

In terms of mechanical development, particular care must be taken to ensure high-precision positioning of the imaging modules. Likewise, the position of internal components is also a key design parameter, not least in the smallest detectors of the product family, with their holistic and uniform liquid cooling.

While DECTRIS was just a start-up, we at ADS Engineering had the opportunity to help the company with the mechanical development and implementation of high-precision X-ray detectors – and, to this day, we develop and prefabricate not only the series-produced products but also special models.

Customer benefits

- Dynamisation of development process

- Synergies in terms of expertise: mechanics, electronics and fluidics

- Support and advice in unfamiliar areas of expertise

- Realisation of the product family

- Rapid prototyping models

- Production partner

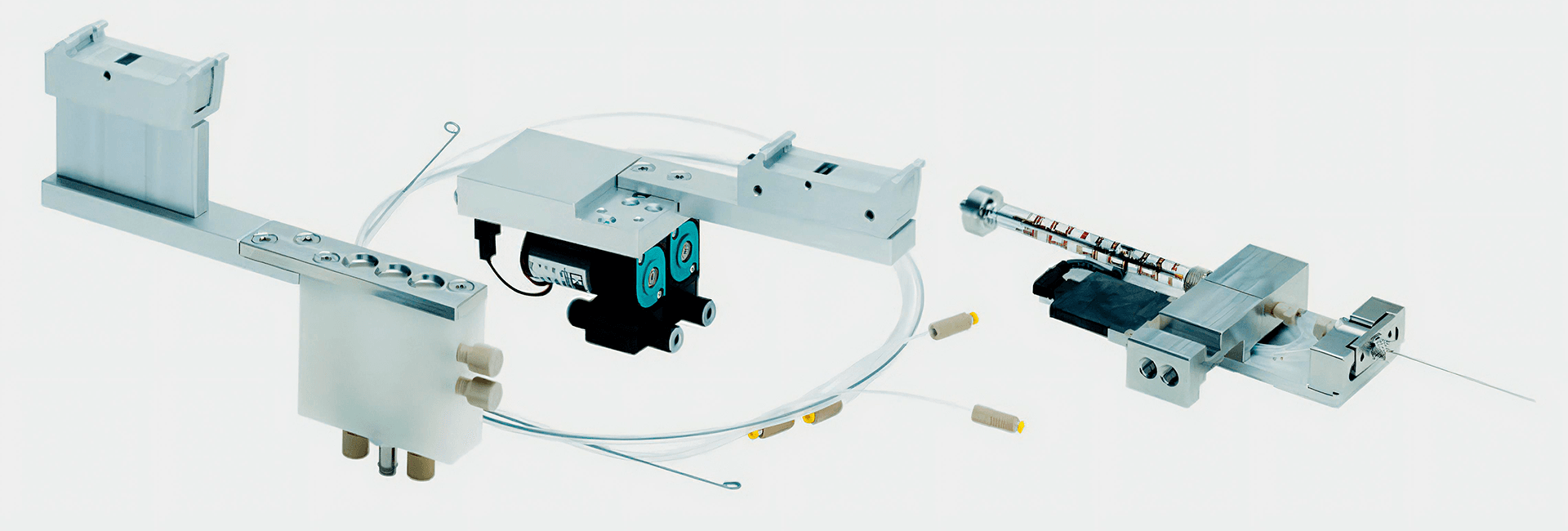

Dosing | Life sciences

Low-contamination dosing unit

Task

Modern mass spectrometers are so sensitive that contamination of samples by previously analysed substances presents a serious problem. For the Swiss company CTC Analytics, we succeeded in jointly developing and building a dynamic preparation and loading system whose dosing syringe never comes into direct contact with the sample.

Implementation

Working closely with the customer, ADS Engineering developed and tested various methods for avoiding contamination and ensured seamless integration of the new fluid concept into the existing axis system. By testing various functional models at the customer’s facility, we were able to optimise the fluidic connections and verify low-contamination dosing with the help of prototypes.

Customer benefits

Choosing the same development environment and making optimum use of synergies significantly reduced the time taken to achieve production readiness.

Biotech engineering | Start-up

Vollautomatische Partikelmessung

Aufgabe

In der biotechnologischen Arzneimittelentwicklung werden flüssige Proben auf Partikel (1µm -150µm) vermessen. Die heutigen Methoden beinhalten eine manuelle Bearbeitung und eine Zerstörung der Proben, wodurch eine anschliessende Analyse der Partikel nicht mehr möglich ist. Das Start-Up BIONTER hat das ADS Engineering damit beauftragt ein vollautomatisches Partikelmessgerät zu entwickeln, welches zerstörungsfrei misst und die Anforderungen der Standards der FDA 21 CFR Part 11 erfüllt.

Umsetzung

Gemeinsam mit BIONTER wurde ein neues Laborgerät definiert und mittels einem ersten Funktionsmuster die Grundfunktionalität erarbeitet. Nach erfolgreichen Versuchen wurde über einen weiteren Prototyp finale Optimierungs- und Testläufe erarbeitet, wodurch das Gerät seine heutige Form als «EVE» erhielt.

Das Projekt ermöglichte es uns, unsere Kompetenzen der Softwareentwicklung, Mechanik, Elektronik und Fluidik verschmelzen zu lassen. Der Fluid-Handling-Pfad, welcher mit Viskositäten zwischen 1cp-60cp umgehen kann, ist durchaus ein Meilenstein der Produktentwicklung. Die Zerstörungsfreie Messung der Probe ermöglichten wir durch eine Automatisierung des Sample-Handlings und eine vollständige Reinigung des Messpfades mit deren anschliessenden eigenständigen Sauberkeits-Verifizierung. Durch das anschliessende Dispensieren der unverschmutzten Probe in das ursprüngliche Vial wird es dem User ermöglicht die gezählten Partikel durch weitere Geräte zu analysieren.

Für die Steuerung des Gerätes werden neben zwei Microcontrollern (C++) ein zusätzlicher Singlebordcomputer (.net/C#-Applikation) verwendet. Die Bedienung des Gerätes wird durch eine zusätzliche .net/C#-Applikation ermöglicht, welche auf dem User-PC installiert wird und mittels REST(basierter)-API mit der Geräteapplikation kommuniziert. Neben einer eigenen Benutzerverwaltung, Audit-Log, eigenständigen Kalibriermechanismen, konfigurierbaren Methoden und Sequenzabläufen mit anschliessendem detailliertem Report, besticht die Softwarearchitektur durch einen userfreundlichen Updatemechanismus, um stets die neusten Features erhalten zu können.

Kundennutzen

- Entwicklung von Fluidik, Mechanik, Steuerungselektronik und Software aus einer Hand

- Iterativer Entwicklungsprozess mit Validierungsschritten durch Funktionsmuster und Prototypen

- Schlankes und agiles Projektmanagement

- Testaufbauten und Testlabor bei uns im Haus

- Produktion und weltweiter Versand der Geräte von unserem Standort

Device development | Product development

Feasibility study smart pillbox

Task

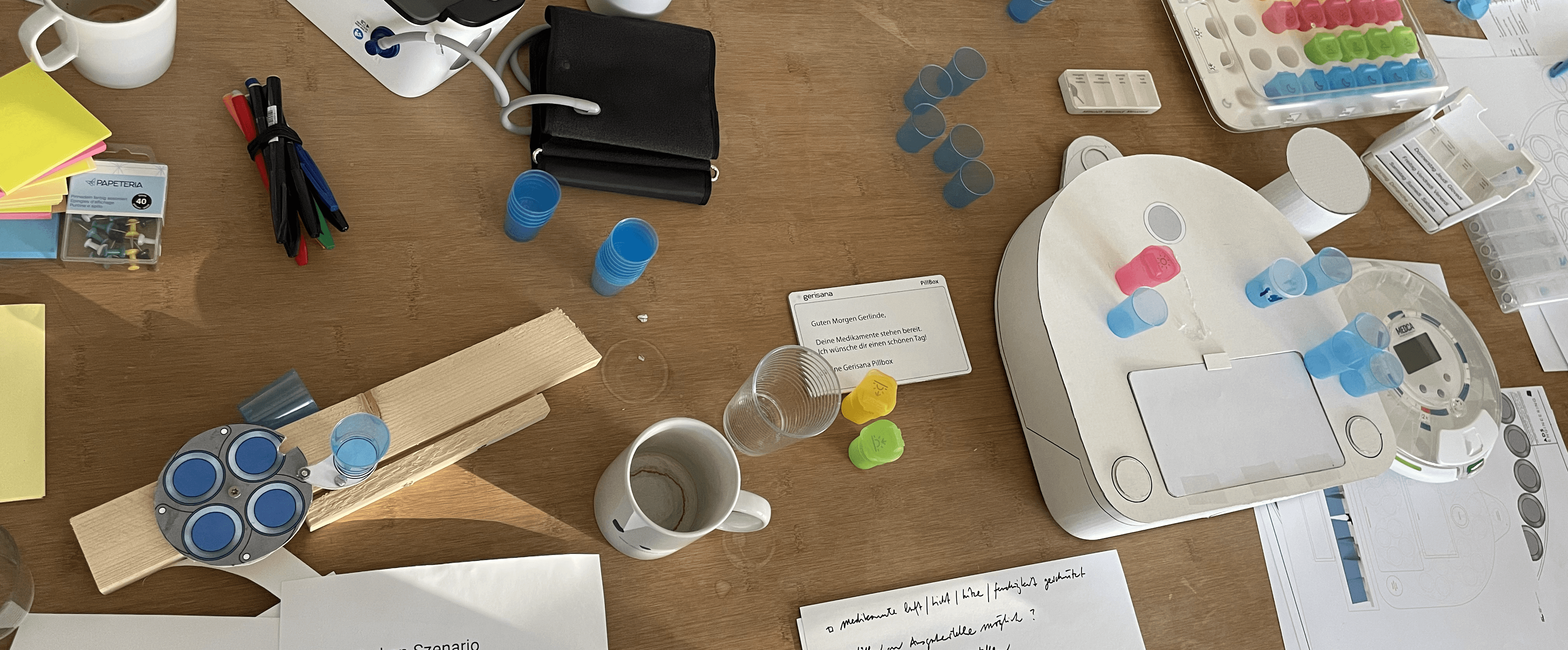

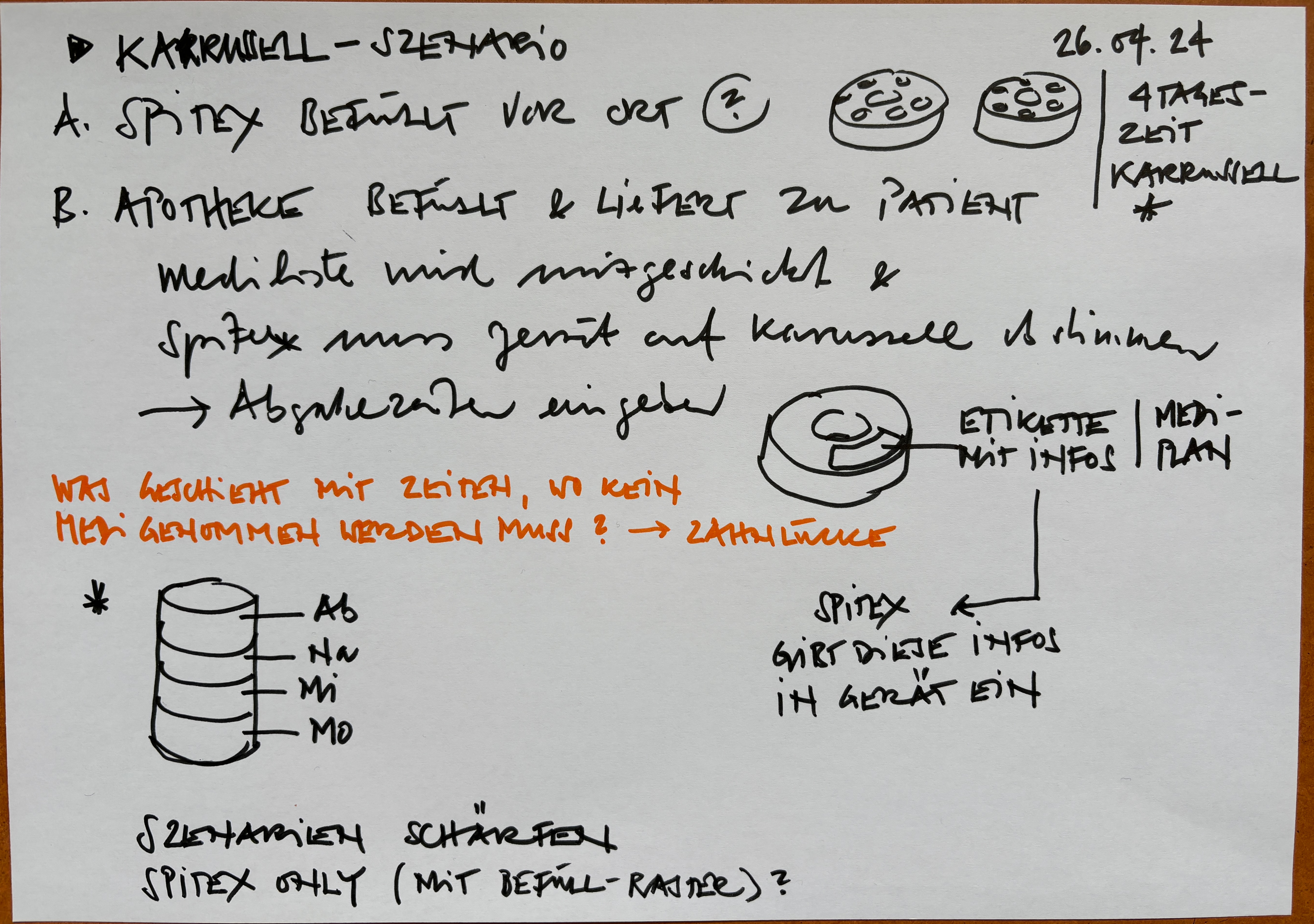

The start-up Gerisana has invented a new type of pill dispenser for the controlled dispensing of tablets. The pill dispenser was designed for use at home and significantly increases the safety of administering and dispensing medication for elderly people.

Gerisana has already gained initial experience with test patients using a prototype. The next step is to develop a new product concept that integrates both existing and new findings and results in an industrially manufacturable medical product.

Realisation

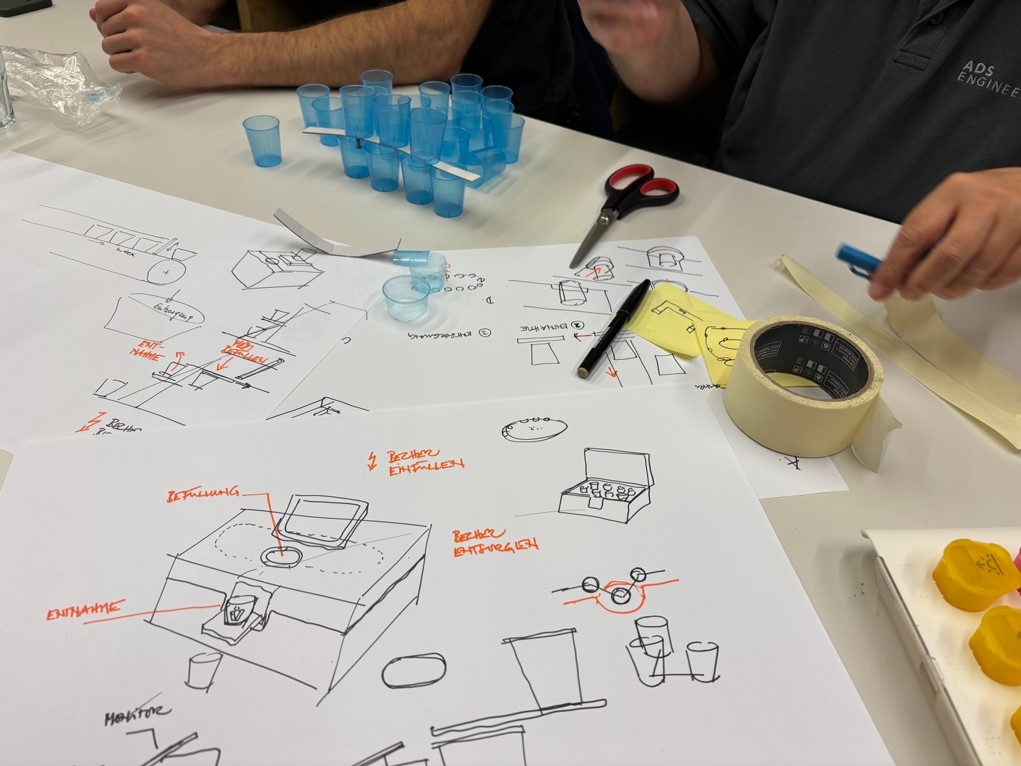

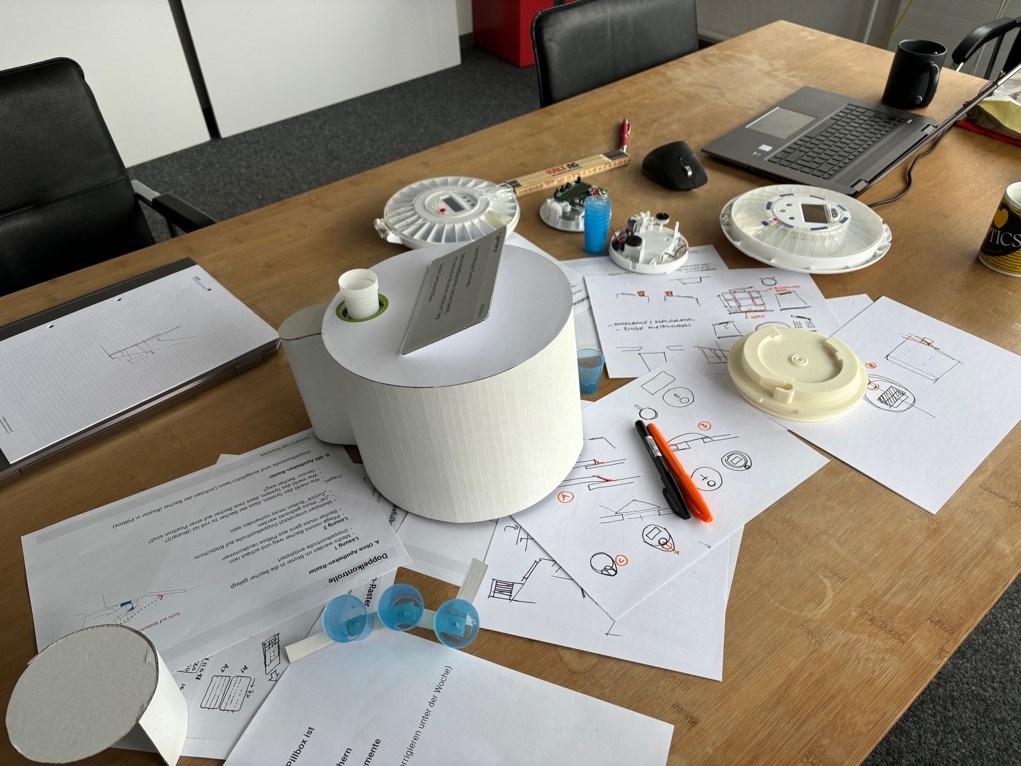

In collaboration with HKT Design, ADS Engineering conducted a comprehensive study for Gerisana on a fully automated and patient-friendly pill dispenser. The focus was always on market requirements, usability and target costs. All development steps were carried out iteratively, which enabled continuous refinement of the insights gained. At the same time, important clarifications were made regarding the electronics platform and the display to ensure that all technical and standard requirements were met.

Another focus was on the development of the design, with equal consideration given to technical feasibility and user-friendliness. Operating concepts were brought to life with functional prototypes and cardboard models. The manufacturing costs were determined on the basis of a detailed solution, which allowed Gerisana to use this information to test the market. Overall, the development process in this project was carried out using user-centred methods and in close cooperation with our customer Gerisana.

Customer benefits

- Results were developed step by step, from rough to detailed, always based on well-founded information

- Development was based on user-centred design

- A clarification of technical and commercial aspects in the areas of electronics and mechanics was carried out early in the project

- Emphasis was placed on ensuring planning capability for further project steps

Start-up | Product development

Software for lab device

Task

A young Swiss start-up needs a complete software solution for its innovative laboratory measuring device, consisting of device software and user software. The device software should interact with the hardware, monitor the measurement process and measure the sample under defined conditions in a specified sequence. The user software is used to record measurement tasks with their parameters and to manage measurements.

Realisation

ADS developed a solid software architecture as the basis for the implementation, which includes a hardware-related measurement and control part as well as a REST API for communication between the laboratory device and the operating PC.

The device software monitors the measurement process and interacts with the hardware to measure the sample under defined conditions. It controls the linear axes and pumps and records precise measurement data from the sensors in the measurement path. After a measurement, a complete and signed pdf report is generated on the device, which ensures that measurement data cannot be manipulated.

The operating software enables the user to define measurement processes in advance and manage them efficiently. A central element of the overall solution is the implemented user administration and the audit trail in accordance with CFR 21 Part 11 in order to fulfil the necessary compliance standards.

The software was implemented by the developers at ADS Engineering mainly in C#, although C++ and Python were used for individual components. The development process was carried out in very close and agile collaboration with the start-up's employees, which ensured the necessary target orientation. Successful tests with end customers confirmed the stability and user-friendliness of the software. It meets the requirements of a modern and powerful solution.

Customer benefits

- Short development cycles thanks to parallel development of the hardware-related measurement part and the operating software in the same ADS development team

- Solid and scalable architecture, tailored from the ground up to the requirements of the solution

- Compliance requirements are met

- Agile and effective implementation by our software team

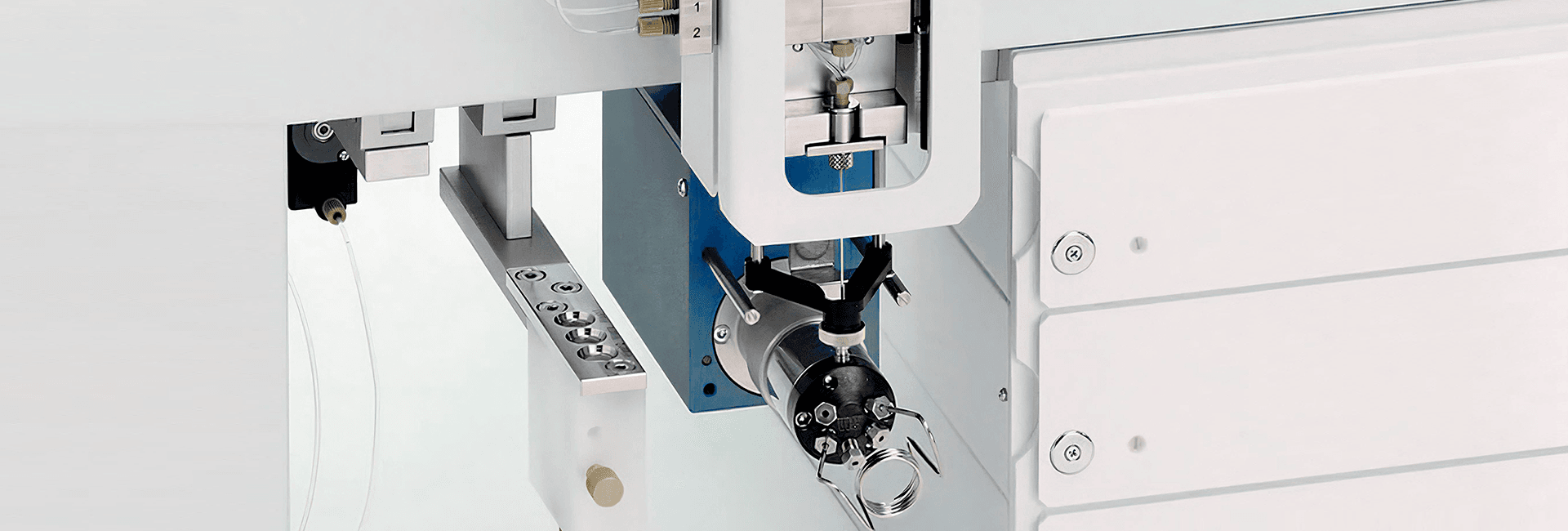

Device development | Life sciences

A unique solution for active substance extraction

Task

In the search for new medicines, the pharmaceutical industry systematically analyses biological tissues with a view to identifying promising molecules. For a Basel life sciences company, ADS Engineering designed and implemented a fully automatic centrifuging and pipetting system for the extraction of active substances from fungi.

Implementation

Working with the customer, ADS Engineering developed and tested various methods for avoiding contamination. Right from the outset, key aspects of feasibility were examined in discussions with the client. Foresighted design ensured that the new system could be installed on site with no need for modifications to the building.

Customer benefits

In the space of just eight months and in direct competition with manufacturers of pipetting systems, ADS Engineering realised a customer-specific layout that met 100% of the customer’s needs. This optimised solution also turned out to be the cheapest among all the suppliers.

Device development | Life sciences

Analysis system for the life sciences

Task

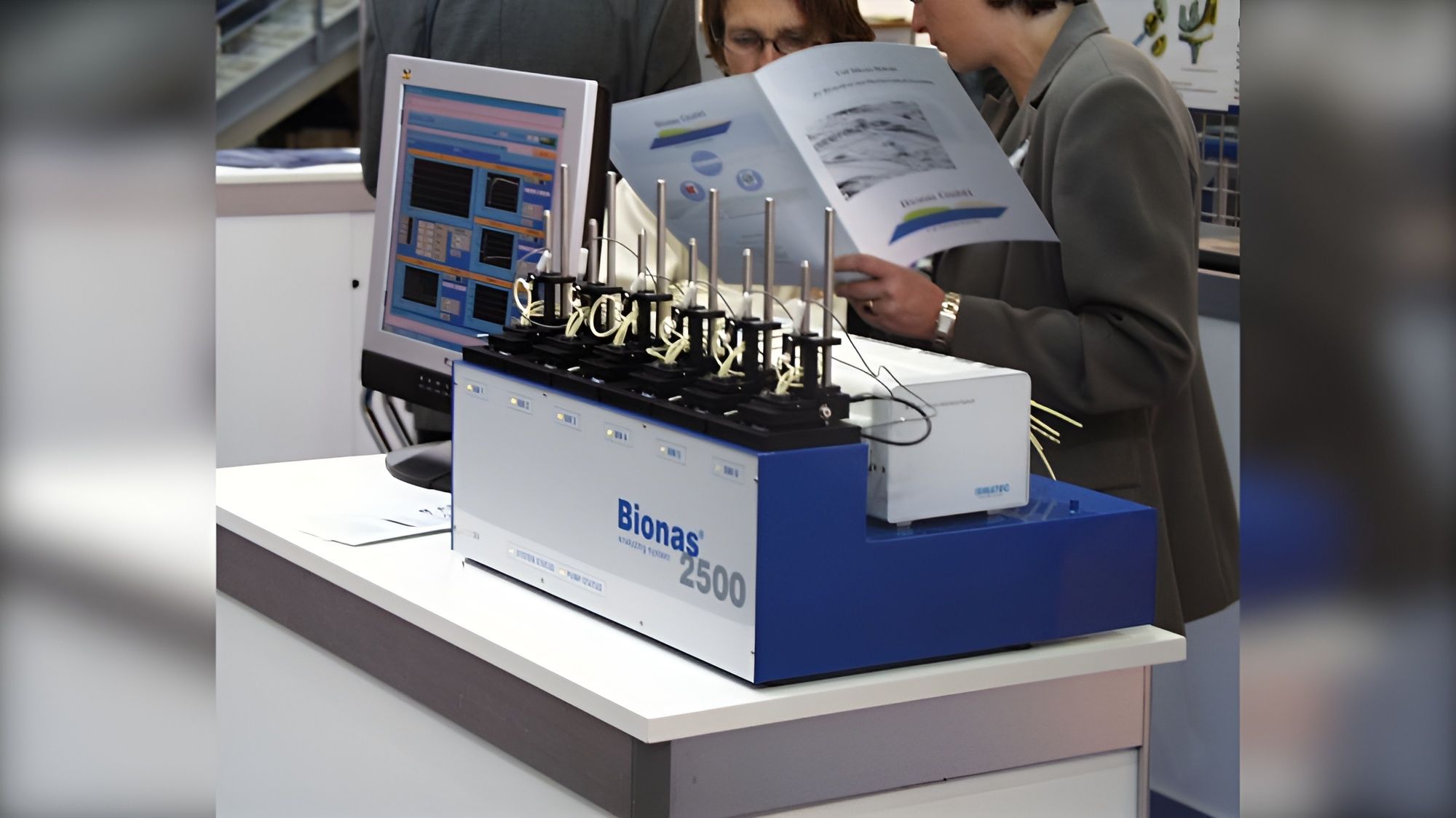

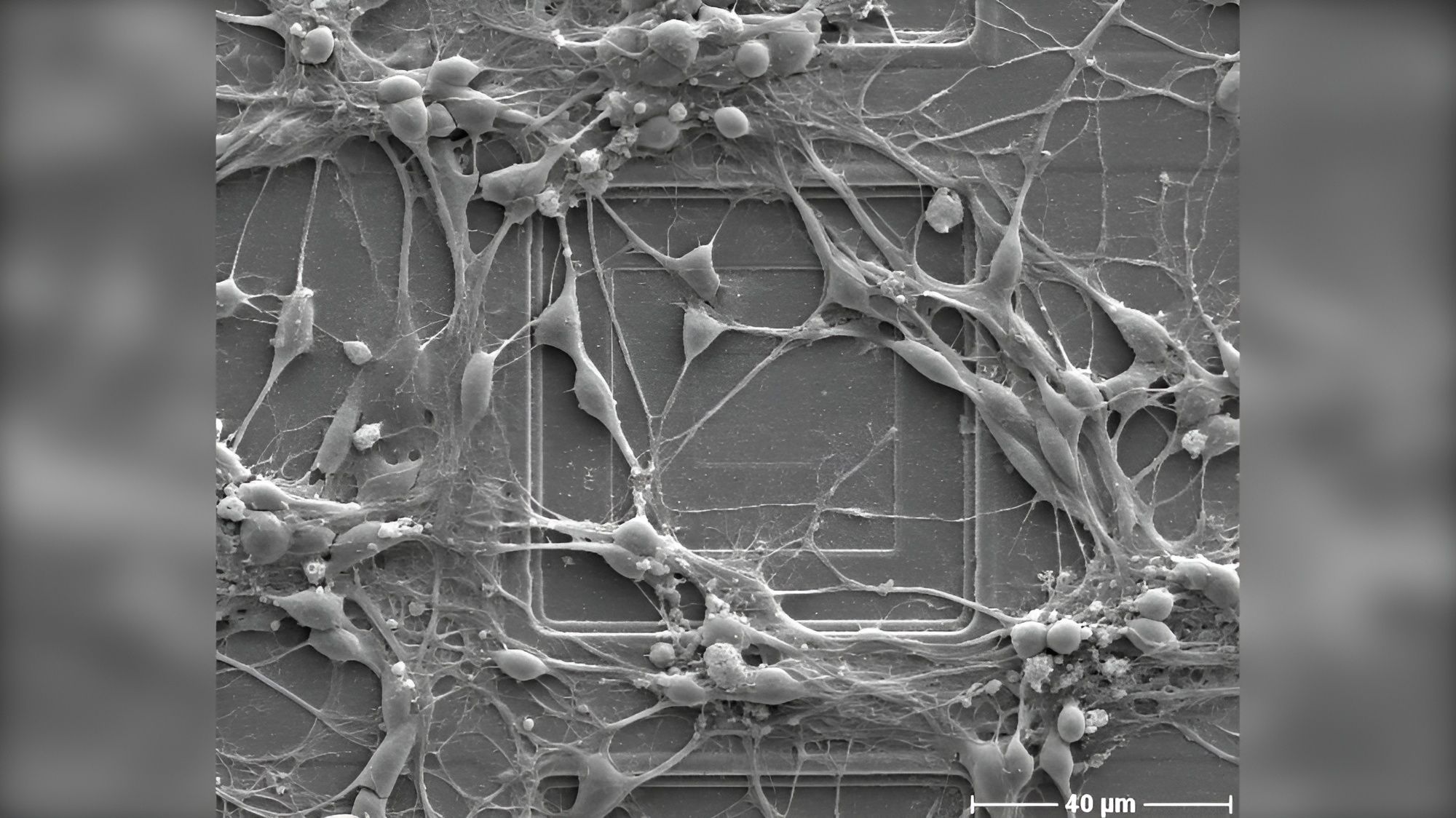

The German biotechnology company Bionas specialises in the manufacturing of metabolic biochips that can be used to measure the vitality of living cells under the effect of medication.

Implementation

The team from ADS Engineering developed a prototype analysis system around the Bionas biochip and completed process validation within 10 months. Further development into a mass-produced device was realised under the guidelines of ISO 13485 certification. Handling and unsupervised operation were documented and verified.

Customer benefits

- Laboratory (proof-of-concept) setup

- Prototype development

- Verification

- Validation

- Device development

- Certification

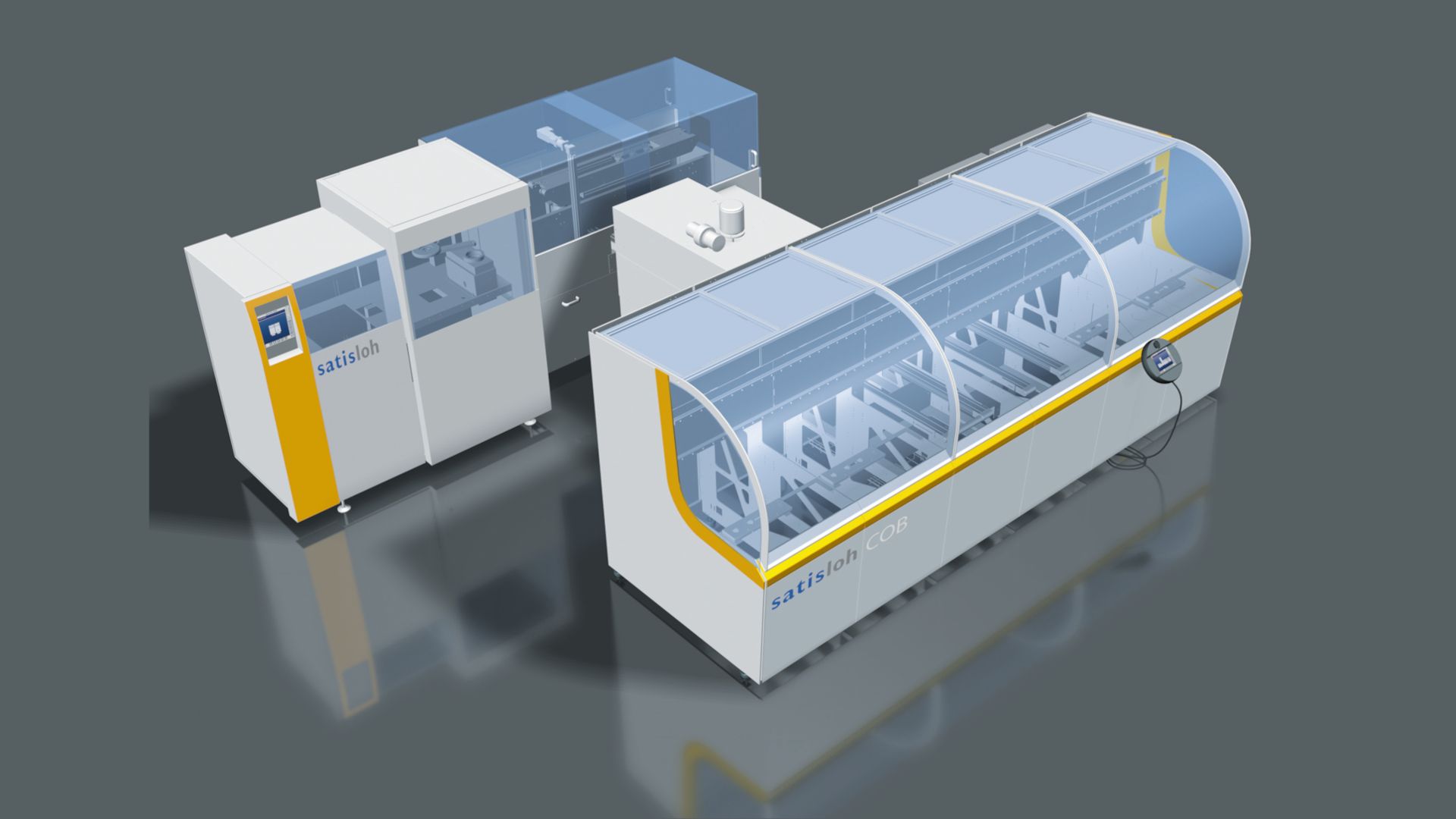

System development | Industry

Process integration thanks to system development

Task

Satisloh, the leading manufacturer of complete solutions for the ophthalmic industry, has succeeded in developing a semi-finished product that need only be machined on one side.

Implementation

ADS Engineering was commissioned to design and produce a system that received the special semi-finished products and, after performing several processes, outputted the lens with the finished coating. As the general contractor, ADS Engineering was responsible for all aspects of the project and developed the hardware, control electronics and software for this unique automation solution. Following successful acceptance of the prototype, the pilot series of the system is now in use at key customers.

Customer benefits

- Feasibility study

- Solution evaluation

- Derivation of corresponding project

- Development

- Implementation

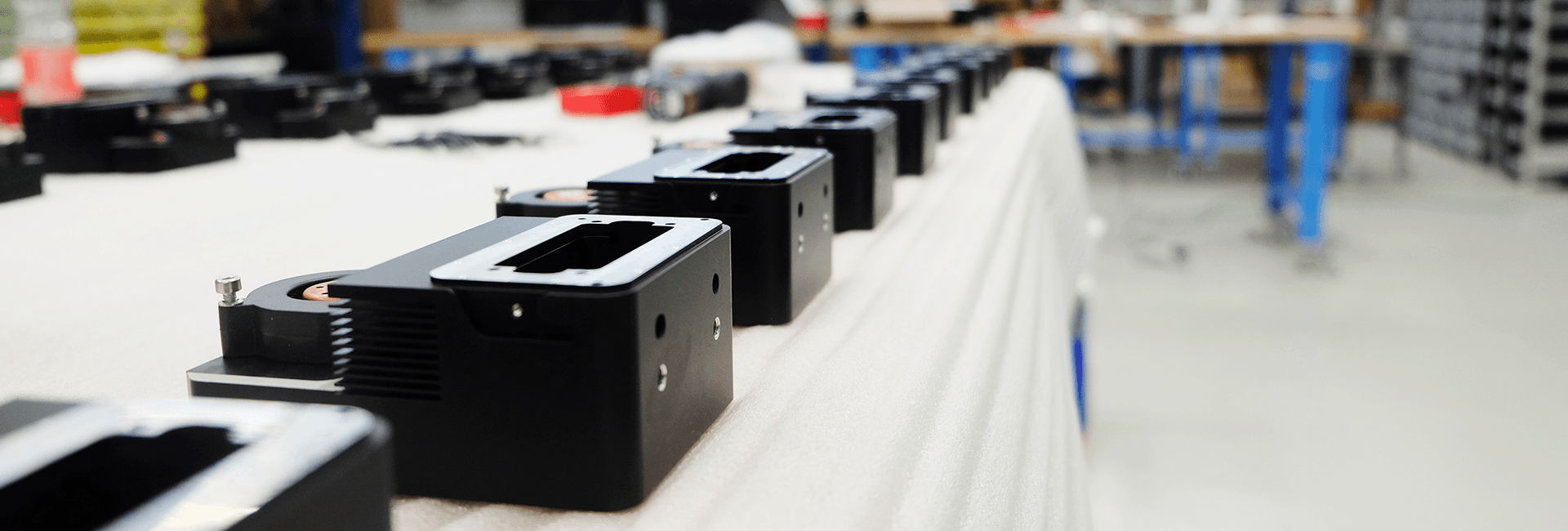

Product family | Device development

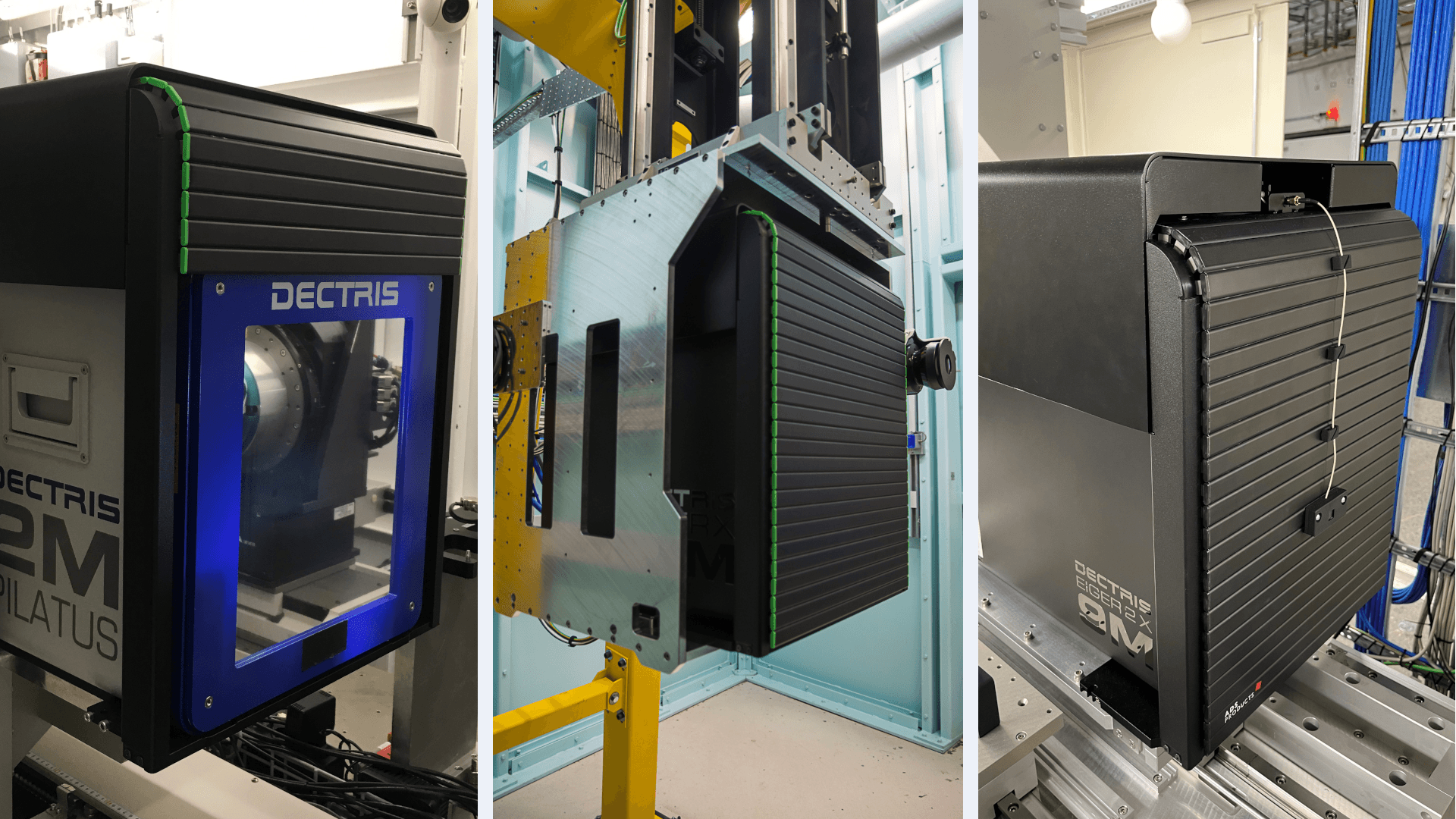

Detector cover

Task

The high-tech X-ray detectors from Dectris AG are positioned in “hutches” – small experimental rooms – at the exit of a synchrotron. In these rooms, the samples for analysis are placed in front of the detector and particles are fired at them. During a sample change or refitting work, the X-ray detectors stand unprotected in the room. To protect the detector, with its sensitive mylar film and the detection electronics behind it, the plan was to develop a stable, slender and automatic cover. This was to be designed so that it could be installed on a PILATUS or EIGER detector as new or retrofitted equipment.

Implementation

The development of the detector cover took the form of a classical product development process. Based on the customer requirements for protecting the high-tech detectors from the front, there followed an ideation process that resulted in various product concepts. By defining the framework conditions and consulting potential customers, the product concept was specified and converted into a 3D model. Following production of the first prototype, the product then underwent thorough validation and testing. After acceptance and industrialisation of the prototype, there was nothing standing in the way of a successful market launch.

Customer benefits

- Detector and Detector Cover are matched to each other

- Very slim construction

- Only 8mm dimension to the detector front

- Easy operation

- Easy installation

- Standard integration option (24VDC digital I/O)

- Hook for ergonomic transportation

ADS Products GmbH is responsible for production and sales of the detector cover.

Contact us and protect your X-ray detector!

ADS Engineering GmbH

Advanced Design Solutions

Hohenrainstrasse 12A

4133 Pratteln 1

Switzerland